|

|

| Technology |

|

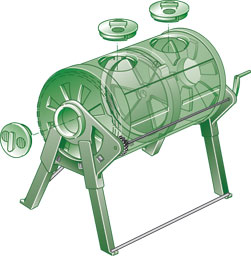

SUN-MAR’s Autoflow technology on 200 and 400 models combines the best features of both pile and drum type composters.

The patented double drum ensures that as the drum rotates, compost moves along the main outer drum and back through the inner drum, before dropping from the output port.

How Does this Work?

200 and 400 Units

The 200 and 400 units consist of an outer main drum, with an inner drum inside it, supported at both ends by the outer drum. The whole drum assembly is supported by a cradle. At the far end of the inner drum is a “scoop” designed so that as the drum rotates, material is picked up by the inner drum and pushed along the inner drum to the output port. When the outport port door is unscrewed composted material falls out into a container.

| 200 Inner Drum |

400 Inner Drum |

|

|

|

- The output end is featured here.

|

- The scoop end is featured here.

|

The inner drum picks up more material as the level of compost in the outer drum increases. The amount it picks up and conveys to the output port is also dependent on the number of rotations of the outer drum. This means that material travels automatically in a circular fashion before exiting the composting unit through the output port. This kind of continuous flow, means that material can be added continuously to the composting drum.

The output port is the output end of the inner drum which is surrounded by the cradle bearing into which it fits snugly. At the other end a 4" bearing on the outer drum fits into the a hole in the cradle, and is supported by a drum cap which prevents the drum from working its way out of the cradle.

Because the scoop is at the far end of the drum, compost is not picked up by the scoop until it has traveled the length of the drum from the input port end to the scoop end. Once the material gets into the inner drum it tends to dry out as it is conveyed back to the input/output end because it is separated from receiving any new moisture.

600 Unit

The 600 is different from the 200 and 400 in that it has no inner drum. Instead it has a divider with three holes that can be either opened or shut. With the divider open the unit is in continuous flow mode. Here, material builds up in the first chamber. Then, as the drum rotates material moves though the holes in the divider and into the second chamber. When material in this second chamber reaches the level of the bottom of the output port, unscrewing the output port will allow compost to start to fall out.

| 600 operating with divider open |

600 operating with divider shut |

|

|

|

If the divider is closed, both chambers can be used for different batches. Again, when the material in either chamber is above the bottom of the output port, unscrewing the port will allow compost to discharge.

A bearing plate supports the drum at both ends, and the output port is in the center of the bearing. This bearing plate is fitted with rollers which assist rotation and serve to maintain the correct distance between the bearing plate and the drum. The drum is rotated by a 10" handle mounted on the end of a stainless shaft. The shaft has a small gear at either end which engages directly with the gears either end of the drum. The ratio is 10 to 1.

The bearing plates accept legs which fit directly up into the bearing plates. The legs are held in a rigid position by metal supports.

|

|

|

Some features of SUN-MAR’s AUTOFLOW technology... |

|

|

- Compost discharges automatically.

- No waiting for batches to finish.

- Pest resistant.

- Easy to load and turn.

|

|

|

|

|

|

AUTOFLOW provides optimum composting conditions!

|

|

|

|

The SUN-MAR 200 and 400 units make it easy to mix, oxygenate, and distribute moisture throughout, while eliminating the disadvantage of batch production normally associated with composting in a drum.

Material Travel Within the composter.

Because the scoop is at the far end of the drum, compost is not picked up by the scoop until it has traveled the length of the outer drum from input end to scoop end. Once material gets into the inner drum it tends to dry out as it is conveyed back to the input/output end because it receives no new moisture.

|

|

|

|